Choosing a Matched Fraction

fotolia.com

This topic is 150 years old. The author of “Notes of a Gun Hunter” of the Orenburg Province argued in the era of percussion rifles that a gun “loves” not every shot,” hardly understanding the essence of the issue.

The point is that the “matched” shot, minimally rearranging at the choke, avoids additional deformation and produces a better-quality shot. The first scientific substantiations of this pattern were published in 1886 by artillery captain N.A. Chizhikov.

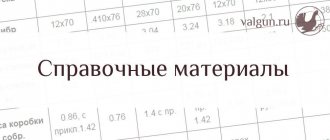

But the history of the issue is not the goal, so I will focus on the last known study conducted by engineer V. Plosky in 1986 with the help of computer technology. The author calculated and tabulated the zones of coordination of the diameter of the muzzle narrowing with the diameter of the shot used.

And although the author calculated only the diameters of the choke constrictions, the table is suitable for determining the consistency of the shot along the entire length of the barrel bore, since for this it is enough to know its diameters. The importance of this coordination was confirmed by famous Russian weapons experts even before the 30s of the 20th century.

I present the table to those ROG readers who are not yet familiar with it.

| photo by the author |

Using the table is easy. Let us determine the shot matched for the diameter of the barrel bore and choke constriction for the Izhevsk gun. Conventionally, the bore diameter is 18.2 mm, respectively, the constriction diameter is 17.2 mm.

In the table, bold lines indicate the coordination zones for a specific fraction number. With a diameter of 17.2 mm, that is, the muzzle constriction, the numbers are consistent: 0; 1; 2; 3; 6; 7. As we can see, the collecting capacity of the constriction is very high.

Next we move towards the ideal - coordination with the diameter of the bore. The fraction number is consistent with it: 0; 2; 3; 7 and 6, because the difference of 01–02 mm can be neglected. But there is one more desirable condition: the fraction must also be consistent with the diameter of the sleeve.

In our example, this condition corresponds to the numbers: 0; 2; 3; 6 and 7. But for a triple, a folder sleeve with a thick wall is desirable. The one, except for the coordination in the muzzle narrowing, does not attract anything and, perhaps, it should be abandoned in favor of adjacent numbers. But in a 16-gauge choke barrel, the unit meets all approval criteria.

| fotolia.com |

All these efforts are done in order to ensure the smoothest possible reconstruction of the shot post along the entire geometry of the barrel and, as a result, minimal deformation of the pellets. This, in turn, determines a sharper, denser and longer-range (within the limits of possible) combat.

Once upon a time N.I. Fokin, publisher of the St. Petersburg magazine “Our Hunt,” wrote that the best concentrator for a choke is a matched shot sprinkled with starch. The shot experiences the main share of deformation while still in the cartridge case. When sprinkled with starch, the shot is, as it were, in a lodgement and “suffers” less - i.e. Most of the pellets retain their spherical shape.

Below is what can be achieved with this method of equipment.

At the end of the 80s of the 20th century, Yuri Maslov, a famous expert on hunting weapons, used Plosky’s table for test shooting with guns: TOZ BM 16 caliber, IZH12 and Bayard 12 caliber. Two options for fraction matching were used. In the first, the shot was consistent with the diameter of the muzzle, in the second - with the muzzle and bore diameter.

The cartridges were loaded as follows. Folder case, “Falcon” gunpowder, cardboard spacers and ungreased felt wads for gunpowder. The latter is especially important for me, because regarding the use of a non-greased wad, I received my share of criticism from “experts” in “ROG”.

| fotolia.com |

There was a third equipment option. The same cartridge case and wads, but polyethylene seals were installed on the gunpowder, and the shot was placed in a polyethylene container. The shot is matched to the muzzle.

According to the results of shooting from all three guns at a distance of 60 meters, all the advantages were given to large shot, consistent with the bore and muzzle, sprinkled with starch. For 16 gauge this is shot numbers 2 and 4, for 12 gauge it is 2 and 3.

Somehow I can’t shoot at 60 meters myself. But I have been using the table for a long time and confirm the possibility of long-range shots with this method of equipment for 12 gauge with shot No. 0, 2 and 3, and for 16 - No. 1, 2 and 4.

Now about using the container. Or rather, about the use of a matched fraction in a container. There is no consensus on this matter, and everyone is free to remain their own. I will share my vision of the subject. It would be foolish to deny that the container is a tool for increasing the range of a shot. protects side pellets from abrasion and compactly “carries” the projectile some distance from the muzzle. I am skeptical about the fact that the cup is an effective protection of shot from overloads.

Many authors note that large shot falls unevenly and advise choosing another container, or wrapping the projectile in paper or film.

Let us turn again to the table, to the lower barrel of the Izhevsk gun with a constriction diameter of 17.7 mm. With this diameter, with a slight stretch, shot Nos. 00, 3, 5, 6, and 7 are matched. We need a cartridge for the goose and for the lower barrel.

Without further ado, you can sprinkle the agreed fraction 00 with starch; you can’t think of anything better for accuracy and sharpness. But what to do with the necessary but inconsistent fraction? In the upper trunk, there is zero grain, consistent with all the canons, sprinkled with starch. There are no two zeros left. According to the plate, the zero is consistent in diameter from 16.7 to 17.4 mm.

Our task is to place the shot at the exit in this zone using the container. A container with petals 0.5 mm thick is suitable for this. If you push this container into the narrowing, the shot will be located in a circle with a diameter of 16.7 mm, i.e. in the approval zone.

My option is 0.25 mm laminated paper petals placed crosswise into the sleeve. That is, the shot is placed in the area of a circle with a diameter of 17.2 mm. In the same way, I agree on fraction No. 2. I explain once again that to calculate the zone, you need to add double the thickness of the container wall to the diameter of the narrowing.

| fotolia.com |

I put a polyurethane gasket 8 mm high in the container for shock absorption, or I compact the shot at the bottom half with starch. And another, important thing: when selecting a container, you need to make sure how the container “feels” at the choke. The petals should be positioned evenly, closing along the cuts.

This is especially true in old Izhevsk guns due to the reduced bore diameters and choke constrictions. If, when passing the muzzle constriction, the petals are deformed and creep onto the neighboring ones, there will most likely not be an even scree. At the narrowing, the petals should be positioned, closing along the cuts. For fitting, I have cylinders with the required diameter and height of 30 mm, and I can select a container without leaving the counter.

What I wrote has undoubtedly already been published in one form or another. But it is quite possible that my publication, supported by personal experience, will seem more useful and accessible to someone than endless links to authorities.

Alexander YARKOVOY, Omsk August 6, 2012 at 00:00

Concordant buckshot. Choosing a Matched Fraction

Buckshot is used to shoot wolves, roe deer, and saiga; Buckshot is also used for hunting lynx, musk deer, and small boar. Loading buckshot cartridges and zeroing a gun with buckshot require certain knowledge, skills, and experience. Without exaggerating, we can say that our hunters have deliberately shot a smaller portion of their guns with buckshot.

Buckshot size

The size of buckshot according to GOST and one of the methods for selecting matched buckshot has already been discussed. However, matched buckshot can be selected in another way: measure exactly the diameter of the muzzle constriction of the left (upper) barrel and, using the table. 43, determine the diameter of the matched buckshot.

For example, if you have a 12-gauge shotgun with a muzzle diameter of the upper barrel of 17.6 mm and you are going to shoot a wolf, for which buckshot with a diameter of approximately 6 mm is recommended, then by looking at the table. 1, you see that for a choke of 17.6 mm (when laying 7 buckshot in a row), the diameter of the matched buckshot should be 5.86 mm. The domestic industry produces two sizes of buckshot close to the size of 5.86 mm: 5.80 and 5.90 mm. To get good results when shooting, it is better to use less dense packing of buckshot. This means that the diameter of the buckshot should be 5.80 mm.

When shooting from shotguns with cylindrical drilling, buckshot

When firing from guns with a cylindrical drill, the buckshot must be coordinated with the bore and placed in rows of 3, 4, 5, 7 pieces, otherwise the accuracy of the battle will be very low. Typically, the impact of a cylindrical barrel is considered satisfactory with an accuracy of 40-50%.

By using a thin paper container with a slightly reduced diameter of buckshot (the buckshot is no longer matched to the diameter of the barrel bore, but to the diameter of the bore minus the double thickness of the paper container), you can increase the accuracy of the fire by 12-15%.

When shooting from shotguns with choke constrictions, buckshot

When shooting shotguns with choke constrictions, it is necessary to match the diameter of the buckshot with the diameter of the choke constriction, and not with the diameter of the bore or cartridge case. If this is not done, then with strong chokes the result is a very bad and inconsistent fight. The fact is that buckshot, coordinated with the bore and laid in correct rows, begins to rearrange and deform when passing the choke (it can even damage the choke).

This results in poor and inconsistent combat. It is desirable that the buckshot is tightly located in the muzzle constriction in 3, 4, 5 and 7 pieces, and in the case it will naturally be located with gaps between the buckshot. It should be noted, however, that the hunter may not always have the required size of buckshot at his disposal and uses the buckshot that he has on hand to load cartridges. In order to also get a completely satisfactory fight with uncoordinated buckshot, there are techniques for artificially matching buckshot with the barrel (if it is a cylinder) or with the choke.

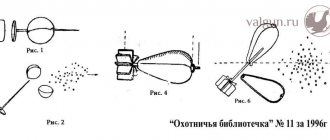

The first method of loading buckshot cartridges

Placing a buckshot shell in a cup or ring made of paper or plastic film. To do this, cut a strip with a width equal to the height of the buckshot projectile (ring) or greater, taking into account the bending of the cut edges of the film under the buckshot projectile (cup), and such a length that the film rolled into a ring fills the gap between the correctly laid buckshot at the muzzle of the barrel, if it is smaller in diameter than required.

If the diameter of the buckshot is larger than required, this leads to the need to reduce the number of buckshot in the row and select the resulting gap (you can leave a small gap, it will not affect the accuracy of the battle) by using the same ring. In addition, such a ring (cup) reduces the abrasion of buckshot on the walls of the barrel when fired. The accuracy of the battle can increase to 24%. All of the above also applies to the use of currently manufactured polyethylene wads with concentrators or separate polyethylene containers. In this case, the thickness of the container petals is already given, and therefore it is necessary to select the appropriate matched buckshot based on the thickness of the petals and the diameter of the choke.

The second method of loading buckshot cartridges

Placement of buckshot in incomplete rows. For example, instead of 7 pcs. Place 6 pieces in a row, that is, without one buckshot in the middle. This method is good with a slightly increased diameter of buckshot compared to the matched one. With a strong deviation towards increasing the diameter, this method does not give such a good scree, but still improves the accuracy of the battle, as well as the speed, since instead of 28 buckshots, 24 are laid. Specifically, this method is as follows. The bottom row of 6 buckshots is laid along the wall of the sleeve (in a ring).

Matched shot or buckshot

In Russia, the term “matched shot” came into use somewhat later, when the process of selecting shot to match the caliber of a weapon became popular among shooters[1]. One of the first works on this topic was the conclusions of artillery captain N.A. Chizhikov, which were published in St. Petersburg in 1886 under the title “The latest improvements in hunting weapons” [1]. Some time later, in 1904, the Russian engineer S. A. Netyksa identified the mathematical characteristics of a matched shot based on calculated data on the pressure in the barrel bore at the time of the shot [1]. His calculations were published in the fundamental work “On the theory of a rifle shotgun barrel and the mechanics of a shotgun shot”[1][3]. In accordance with his calculations, the definition of “matched shot” is suitable for a shot that fits tightly into the cross-section of the barrel bore in the amount of 7, 19, 37, 91 or 126 pieces. Somewhat later, one of the largest pre-revolutionary specialists in the field of gun and hound hunting, A.P. Ivashentsev, simplified the definition of an agreed fraction by excluding numerical values from it [1]. In his book “Combat and Shotgun Service,” Ivashentsev indicated that only those types of shot that can be placed in regular rows inside the bore should be considered consistent [1]. Having systematized the available information on the agreed fraction, another researcher N.I. Andogsky identified two main requirements that it must satisfy [1]:

- ordered arrangement inside the cartridge case with a certain number of pellets per row,

- maintaining the relative position of the pellets in the cartridge case at the moment of firing, during passage along the entire bore of the barrel until it leaves the barrel of the weapon. That is, the shot had to be consistent both according to the internal diameter of the cartridge case and the caliber of the barrel, and not according to any of these values.

In the 30s of the 20th century, the Soviet game manager S.A. Buturlin confirmed the recommendations for using matched shot to achieve the best results in shot quality [1].

In 1986, the Soviet engineer V. Plosky conducted a numerical experiment on the computer selection of matching areas for each fraction number with a diameter from 2.5 to 5.0 mm, presenting them in the form of convenient tabular data [1]. In 1987-1988, to verify this information, small arms expert Yu. A. Maslov conducted a series of full-scale experiments with shooting a large number of cartridges from hunting rifles of various systems (IZH, TOZ, etc.). Based on the results of these tests, it was concluded that V. Plosky’s table makes it possible to select a consistent shot over the entire range of barrel diameters, and not just for the muzzle, as its author himself believed [1].